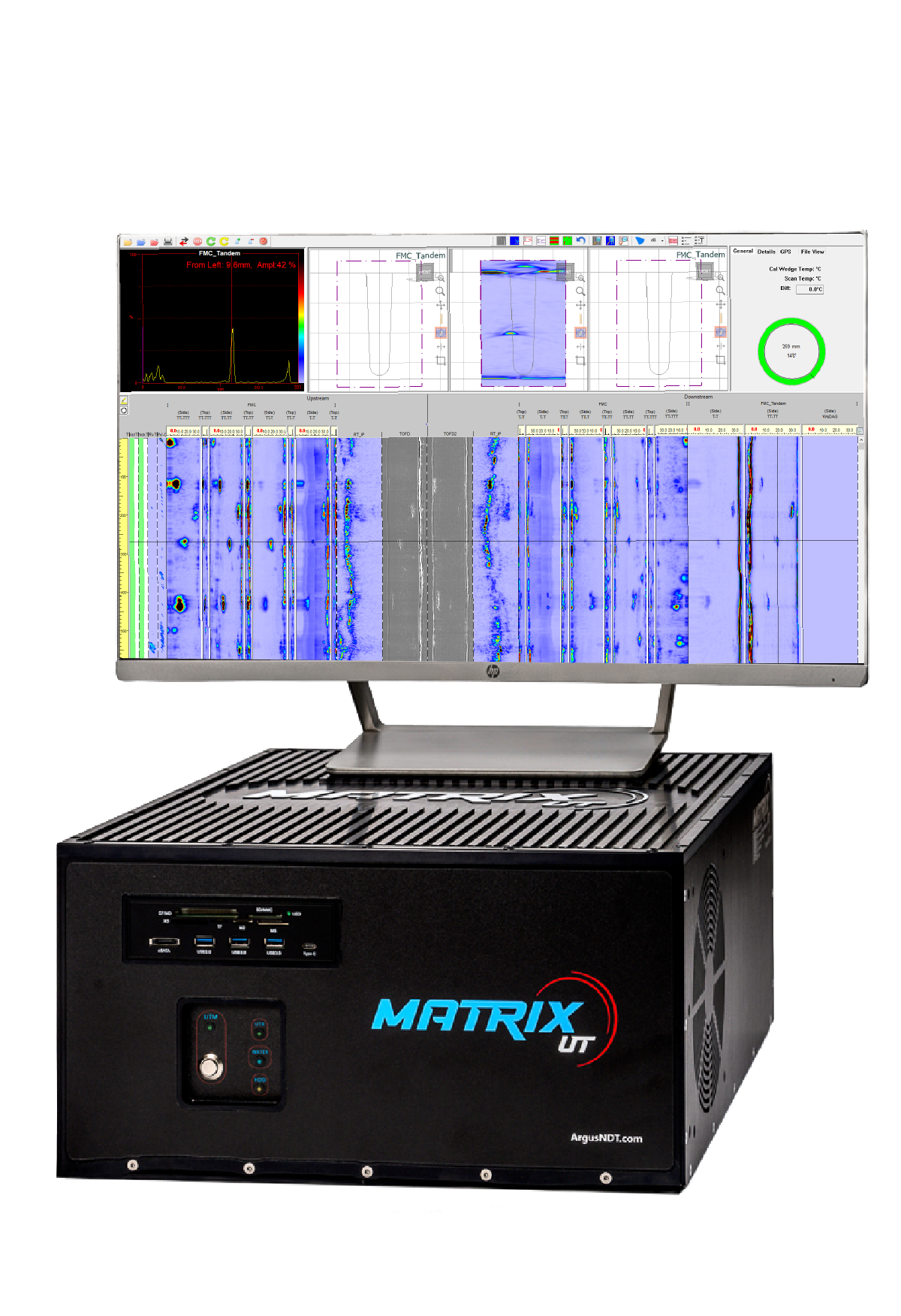

Phased array testing with advanced FMC and TFM technology

The Latest in Phased Array Technology

Comprehensive Inspection Methods

Harness the power of advanced acquisition techniques, including FMC, HMC, PWI, and SAFT, to ensure comprehensive inspection coverage with conventional UT, TOFD, and zonal PA methods.

GPU-Powered Inspection Efficiency

Empower your inspection process with fast and efficient GPU-powered processing techniques, such as TFM and PCI, enabling quick and accurate data analysis for enhanced decision-making.

Accurate Flaw Detection

Pinpoint threats and gain insight into the inspection area with highly accurate identification of flaws and discontinuities utilizing FMC and TFM data modes.

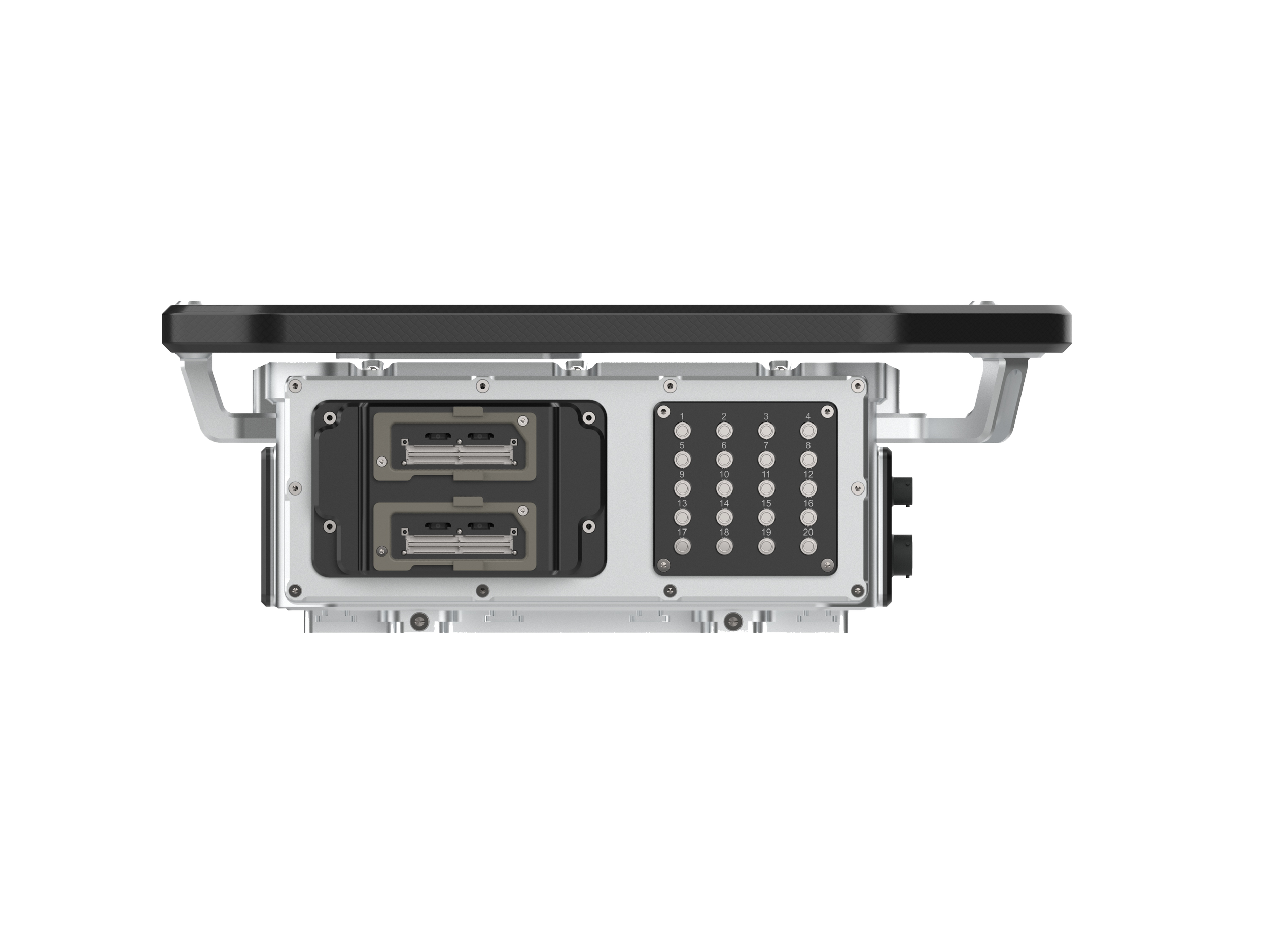

Universal Dual Connectivity Solutions

Streamline NDT operations with universal high-density D-Sub or IPEX connectors, ensuring seamless integration and enhanced flexibility in dual transducer compatibility.

Unleashing the Potential:

Next-Level Phased Array Capabilities and Seamless Connectivity

Introducing our groundbreaking phased array system, Matrix UT, a cutting-edge solution that revolutionizes non-destructive testing and inspection.

Designed to meet the evolving needs of offshore and onshore pipeline inspections, our system combines advanced technologies, precise imaging capabilities, and seamless integration.

Matrix UTR V2 Capabilities

PA and Conventional UT

64:128 Phased Array (PA) channel configuration with parallel firing.

20 Conventional Transceiver Channels to support complex setups.

Connectivity and Interfaces

Universal Dual Connectivity: Streamline NDT operations with universal high-density D-Sub or IPEX connectors, ensuring seamless integration and enhanced flexibility in dual transducer compatibility.

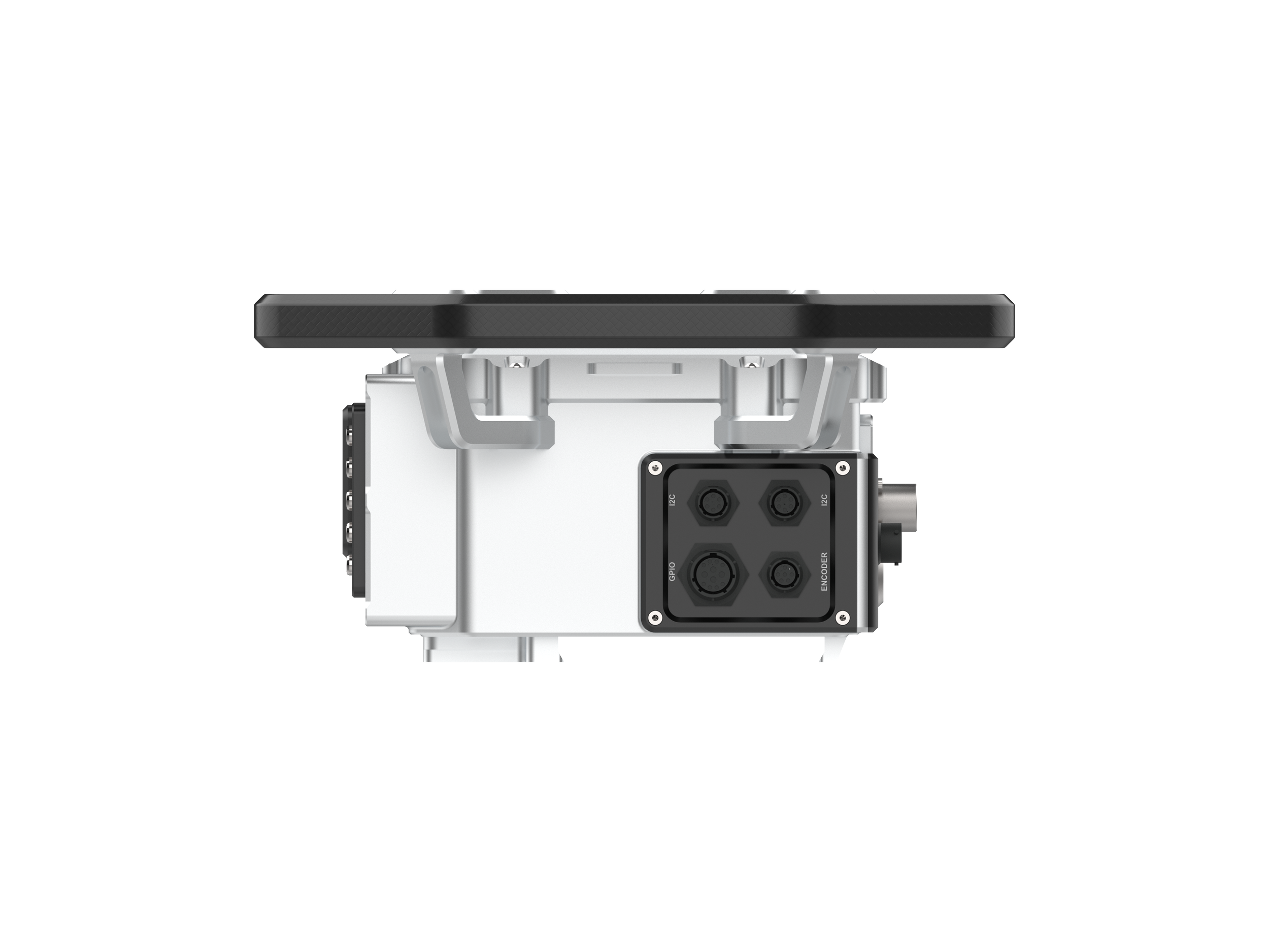

Enclosure

IP67-Rated Enclosure: Ensures reliable operation in varying temperature environments from -40C to +50C.

Rugged, High-Quality Build: The UTR V2 is designed utilizing high-grade materials, advanced sealing, and temperature control, ensuring consistent performance in even the harshest environments.

Encoder and I2C Bus

2 Axis of Encoder Inputs: Supports quadrature and step/direction counting, allowing for pipe scanning and dual-axis corrosion mapping.

Dedicated I2C Bus: Provides a dedicated bus for connecting external sensors like temperature probes or alternative encoders.

Global Positioning System (GPS)

GPS: Integrates a GPS system for tagging each weld/scan with a unique location.

Motor Control and Power Input

Integrated Motion Controller: Allows scanner control (speed, direction and distance) via graphical user interface.

Power Supply: Operates on a single 48V supply, available through the umbilical or auxiliary input.

Umbilical Connector: The umbilical employs SMPTE 304, integrating optical fiber and DC power supply, to facilitate 10 Gb Ethernet for enhanced FMC scanning speeds.

Additionally, the umbilical is offered in various lengths, from 1 meter (+/- 3 feet) to over 100 meters (+/- 300 feet) for hard-to-reach places.

10 Gb Optical Fiber Ethernet Interface: Enables interface with the host computer at high speed via optical fiber.

Wireless Control Interface: Allows system control and access through WiFi connectivity.

Matrix UTM V2:

Delivering Precise Imaging and Efficient Analysis

With its exceptional performance, versatility, and user-friendly interface, our phased array system empowers inspectors and engineers to uncover hidden flaws, enhance productivity, and make informed decisions with confidence.

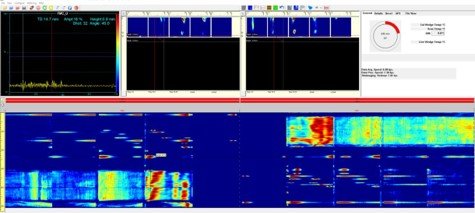

Matrix UTM V2 + Matrix WZ Wizard Software Capabilities

Imaging Techniques

FMC / TFM / PCI: Full Matrix Capture + Total Focusing Method.

PWI / TFM / MIG / PCI: Plain Wave Imaging with TFM and Migration.

Anti-aliasing Imaging: Minimizes aliasing artifacts for improved image quality.

Focal Law and ROI

User-friendly Focal Law Calculations: Simplifies the process of creating focal laws for accurate inspection setups.

Region of Interest (ROI) Selection: Allows users to define specific areas for focused analysis, improving efficiency and reducing noise.

FMC/TFM Visualization

Real-time Data Analysis and Interpretation: User-friendly data presentation with selectable color palettes.

Advanced Signal Processing

Advanced Signal Processing Techniques: Implements advanced techniques for signal processing, enhancing data analysis and interpretation.

Super-resolution TOFD: Enhances resolution and detail in Time-of-Flight Diffraction imaging.

Matrix DS:

Cutting-edge Data Science Software Designed to Enhance Data Analysis and Reporting Capabilities

Unleash the power of advanced analytics and uncover invaluable insights with ease.

Matrix UT Specifications

Housing and General Features

-

Without handle: L=380mm, W=300mm, H=180mm

With handle: L=490mm, W=360mm, H=190mm

-

Operating Temperature: -40 to 50°C (-40°F to 122°F)

Storage Temperature: -40 to 50°C (-40°F to 122°F)

-

8.65 Kg (19 lbs)

-

110-240 VAC 50-60Hz

-

High-Frequency Emission: CENELEC EN 55011:2009+A1:2010 Group 2 Class A Industrial, scientific, and medical (ISM) radio-frequency equipment.

-

Electrical Safety: EN61010-1:2010 Safety requirements for electrical equipment for measurement, control and laboratory use.

-

Accuracy of better than 5 Metres depending upon atmospheric conditions.

Acoustic Parameters

-

Negative square wave 50:25:200 V. PRF 1 Hz to 20 kHz. Pulse width 20:2:500 ns.

2048 Tx Focal Laws.

-

Bandwidth: 0.75MHz to 20MHz (-3dB). Channel crosstalk >60dB at 2MHz.

2048 Rx Focal Laws.

Imaging Techniques

-

FMC/TFM

FMC/PCI

-

HMC/TFM,

HMC/PCI

-

PWI/TFM

PWI/PCI

PWI/MIG

-

DAS

-

Image fusion

Talk to an Expert

At Argus NDT, we are driven to be the best NDT equipment partner you can choose. Reach out to see how our focus to deliver fast and accurate results can save you money on your next inspection operations.